TMU CALCULATOR® – Times are changing.

—————————————————————————————————————————————————————————————————————————-

The first mobile MTM application for tablet PCs that determines target times directly on site.

Tested and confirmed with a top automobile supplier. Please contact us for more information on this.

—————————————————————————————————————————————————————————————————————————-

Prepare your analyses directly on site and transfer them to your system at the touch of a button.

The TMU CALCULATOR® (MTM Software / MTM App) processes pre-determined time systems like

- MTM-1®

- MTM-UAS®

- MTM-MEK®

- MTM-SD®

- MTM-LOG® (Logistics)

- MTM-Visual Inspection

as well as customer-oriented time modules like

- Mercedes-Benz/ Daimler C-Values,

- BMW SD (Standard Data),

- GSD – General Sewing Data

- many more…

The data export from TMU CALCULATOR® is compatible with time management programs including

- TiCon

- TAKTIQ AssemblySuite

- CAPP

- Delmia

- TMU LOCALIZER (*under development)

High data quality through integrated sets of MTM rules and error notifications.

—————————————————————————————————————————————————————————————————————————-

“Who actually optimizes the process optimizer?”

The basic idea in developing an MTM application as a tablet solution was to develop a software package that’s functional and intuitive to use, and that makes the process for preparing MTM calculations more cost-effective and more comprehensible for third parties . This is why we also placed special importance on making the solution transparent to and understandable by production employees, so as to achieve higher acceptance for MTM. “Increase your productivity by using the right equipment.”

—————————————————————————————————————————————————————————————————————————-

About the TMU CALCULATOR®

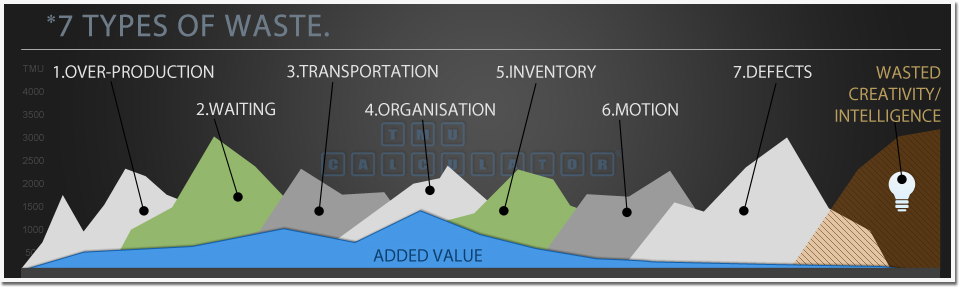

The device processes pre-determined time systems (e.g. MTM) and thus provides the user with reproducible methods that include a clear method-time relationship. It is especially well-suited for pointing out wastefulness over the entire value-added chain, lowering unnecessary costs and increasing the competitive ability.

As its productivity is greater than that of conventional analytical methods, the TMU CALCULATOR® is an optimal instrument in supporting continuous improvement processes.

*TMU = time measurement unit

Inspiration for development

The factors that drove development of the TMU CALCULATOR® were solutions that were “tried and tested” and complete. Again, these included current methods for preparing MTM analyses and process modules with different types of level II data and their compression previously: documenting processes on paper, typing this into the recording system, verifying with timer modules.)

The fact that the application of the MTM method, which has been very successful up to this point, was by and large spared the continuous improvement process (CIP) can certainly give the impression that the method is clearly practicable, dependable and free of any wastefulness. More specifically, the method can provide scarcely none or no optimization approaches whatever in the sense of CIP.

So in this case, at least the last items of the “7 Types of Waste” (*) are subject to the common “copy instead of understand” principle. Here one just had to turn around the binoculars and ask themselves how can I, as the “process optimizer”, optimize.

Granted, this sentence sounds strange and discouraging, and is certainly the reason why a driver of the CIP process was, up to now, discouraged and preferred to focus his/her complete attention on the “green pastures” and “lean productions” of other parties. However, you don’t have to be an MTM practitioner, corporate consultant or lean guru to know that it’s a lot easier to point third-party “problems” than to tackle one’s own.

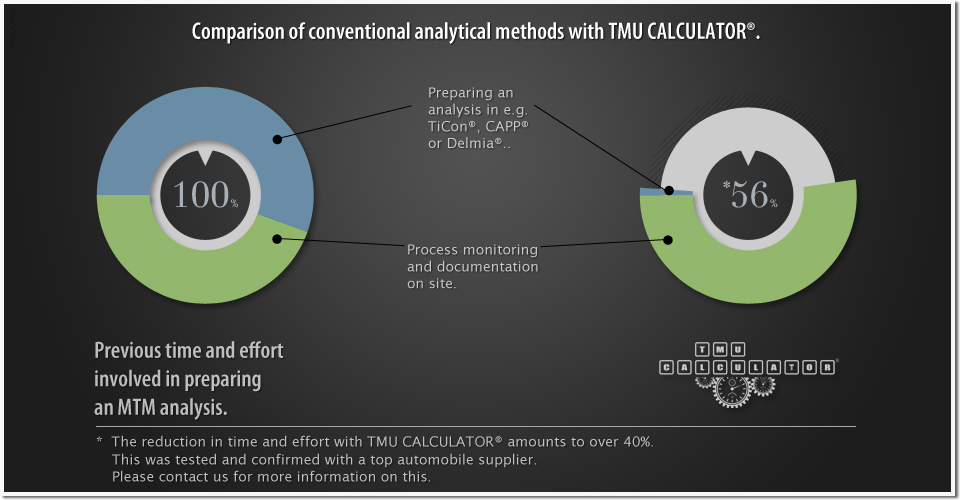

What it thinks

The idea in development was therefore not to question MTM as a pre-determined time system, but rather entirely the opposite—to optimize the use of the up to now successful, and rightly so, MTM process for calculating industrial production processes. We did this by shortening the path from process monitoring on site, through documentation of individual process steps on paper, up to their representation on the PC for CIP purposes. In this way, process paths, unnecessary waiting times and quality defects could be reduced to a virtually insignificant magnitude. This in turn would lead to a high productivity increase in preparing MTM analyses.

What guides it

Our goal is to generate an added(-value) service and increase in productivity in work preparation (WP) or manufacturing engineering (ME) which is already omnipresent in production. Our product development process has the goal of providing employees with the ability to focus more on ergonomic workplace design, employee training in accordance with established target processes and implementing possible areas of potential. This will generate added value for the company or the customer, and ensure competitive ability over the long term.

What makes it better

If you consider just the time and effort expended for preparing an MTM-based analysis, the reduction in effort provided by the TMU CALCULATORS® amounts to over 40% as compared to common methods of analysis. This productivity should be of benefit to mid-sized companies that, for reasons of cost and profitability, forego implementation of a performance-based compensation and need to switch to a REFA time recording system or estimated times. For that reason alone, we feel it’s essential to optimize the methods for preparing an MTM-based analysis, and thus keep the costs for MTM implementation low and profitable from a business standpoint.

—————————————————————————————————————————————————————————————————————————-

Technische Features

—————————————————————————————————————————————————————————————————————————-

Compatibility

![]() The TMU CALCULATOR® processes systems including MTM-®1, MTM-UAS®… and is compatible with time management recording systems such as TiCon, CAPP, and Delmia.

The TMU CALCULATOR® processes systems including MTM-®1, MTM-UAS®… and is compatible with time management recording systems such as TiCon, CAPP, and Delmia.

Configuration

![]() In addition to conventional MTM data, the TMU CALCULATOR® lets you use your own data cards and time modules. As a result, you have no limits whatsoever in creating complex level II data.

In addition to conventional MTM data, the TMU CALCULATOR® lets you use your own data cards and time modules. As a result, you have no limits whatsoever in creating complex level II data.

Productivity

![]() Increase your productivity by using the right equipment. The TMU CALCULATOR® saves you time in preparing MTM-based analyses, up to 50% in comparison to conventional methods.

Increase your productivity by using the right equipment. The TMU CALCULATOR® saves you time in preparing MTM-based analyses, up to 50% in comparison to conventional methods.

Operation

![]() Using the calculator is transparent and intuitive, allowing users to get started quickly with a low training effort.

Using the calculator is transparent and intuitive, allowing users to get started quickly with a low training effort.

Transparency

![]() Analytical standards, an integrated set of rules including error notification and a selection of MTM time modules that is comprehensible even for outsiders unfamiliar with MTM ensure high data quality.

Analytical standards, an integrated set of rules including error notification and a selection of MTM time modules that is comprehensible even for outsiders unfamiliar with MTM ensure high data quality.

Data input

![]() The TMU CALCULATOR® has a keyboard with a memory, allowing you to store additional component descriptions from f.e. SAP®. This saves you time and enables process descriptions to be standardized throughout.

The TMU CALCULATOR® has a keyboard with a memory, allowing you to store additional component descriptions from f.e. SAP®. This saves you time and enables process descriptions to be standardized throughout.

Photo/video function

![]() The device’s integrated photo and video functions enable you to document process steps pictorially. Prepare MTM-based analyses, standard process sheets and training documents in a single step.

The device’s integrated photo and video functions enable you to document process steps pictorially. Prepare MTM-based analyses, standard process sheets and training documents in a single step.

Sending e-mail

![]() Send your MTM analyses at the touch of a button, directly from the process monitoring site.

Send your MTM analyses at the touch of a button, directly from the process monitoring site.

PDF printout

![]() The TMU CALCULATOR® makes it easy to print out your results and get your production personnel involved directly. This allows you to generate transparency as well as trust in the MTM process recording process.

The TMU CALCULATOR® makes it easy to print out your results and get your production personnel involved directly. This allows you to generate transparency as well as trust in the MTM process recording process.

—————————————————————————————————————————————————————————————————————————-

Trademarks

—————————————————————————————————————————————————————————————————————————-

TMU CALCULATOR®, TMU LOCALIZER® and CUT CORNERS® are registered trademarks.

The TMU CALCULATOR® interface is uniform and sophisticated with an artistic design, and is registered as a design patent. As such, the entire interface must, for the most part, be classified as a work type of technical representation. This work type is not tied to one display format and includes the entire interface, even though it is full recognizable only by switching the display contents multiple times. It also characterizes the product advertising and packaging for the TMU CALCULATOR® branded product.

The third-party software and hardware names mentioned on this page are registered trademarks and must be treated as such.

The Cut Corners® company is represented by the international law firm and trading partner Taylor Wessing. Taylor Wessing.